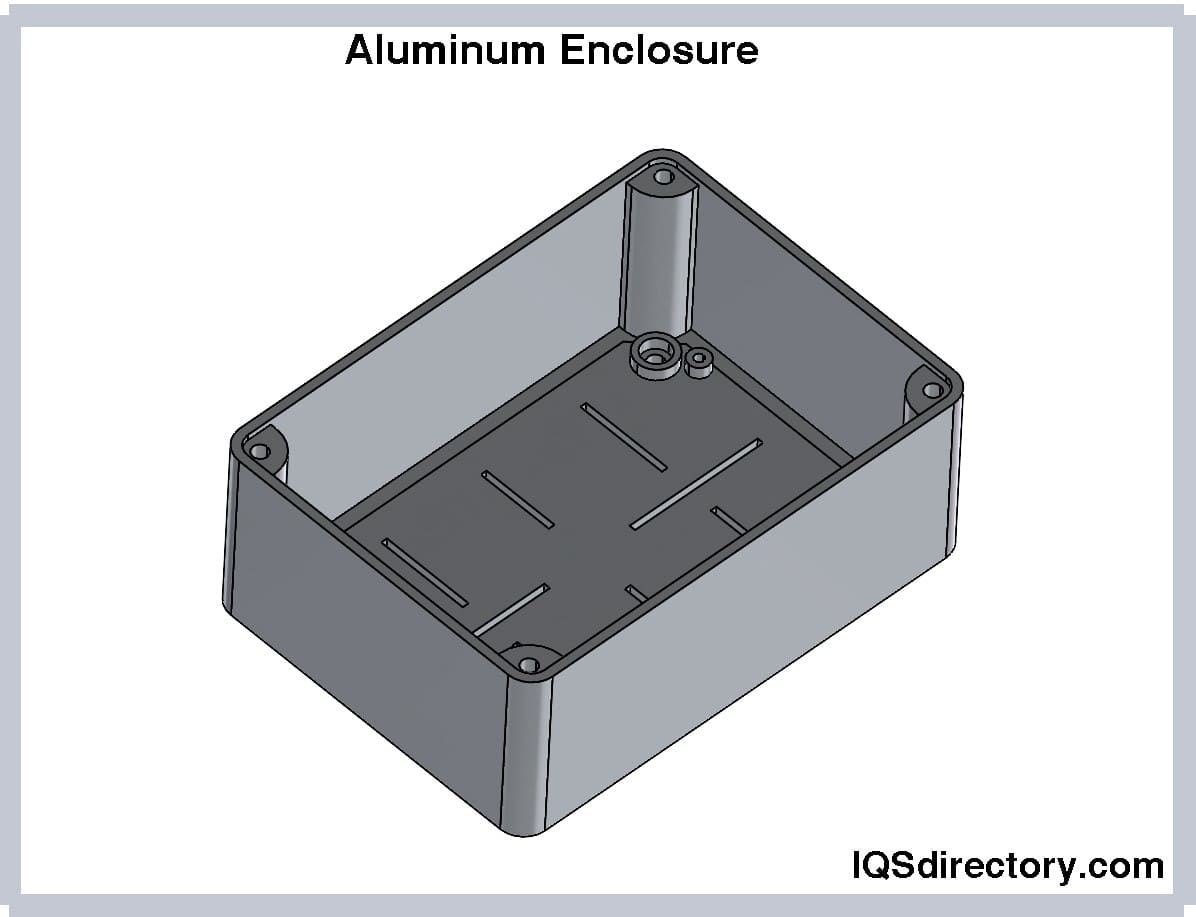

Electronic instruments and other equipment are housed in aluminum enclosures that guard against interference or damage. These enclosures must safeguard their contents from various weather conditions and grime and dust because they can be utilized indoors and outside. Electromagnetic interference (EMI), if not insulated, can impair the functionality of the equipment inside the enclosures. Read More…

Maysteel provides complex sheet metal fabrication with a focus on design for manufacturing. Founded in 1936, we combine our extensive engineering experience and market knowledge with an expanding supply chain footprint, allowing us to fabricate products that others can’t. We design, engineer and manufacture custom OEM sheet metal enclosures, kiosks, cabinets and racks. We have locations in the...

ROLEC Enclosures Inc. is a leading manufacturer of electronic enclosures. We work without clients’ needs and requirements to find the best solution for them. We also make fully customized enclosures to be ready for use immediately. Give us a call today learn how ROLEC Enclosures can help you will all your enclosure needs.

AutomationDirect.com takes pride in being a trusted partner for businesses seeking reliable electronic enclosure solutions. Our team is dedicated to providing exceptional customer service and technical support to ensure that our customers find the perfect products to meet their needs.

With over 80 years of collective expertise, AMCO Enclosures stands as a pioneer in crafting and delivering top-notch electronic enclosures. Our forte lies in electronic packaging, server rack, network rack, and containment manufacturing, making us the go-to choice for diverse industries.

At Accurate Metal Fabricating, we specialize in crafting precision-engineered electronic enclosures that meet the unique demands of modern industries. With a relentless commitment to quality, we pride ourselves on providing cutting-edge enclosures that safeguard electronic components with unparalleled accuracy. At the heart of our success is a passion for innovation, driving us to create...

Fibox Enclosure Systems is one of the largest enclosure manufacturers in the world and is the market leader in thermoplastic enclosures used for protecting electrical and electronic components in hostile and hazardous environments. Fibox recently celebrated over 40 years as a designer and manufacturer of thermoplastic enclosures. Besides pioneering polycarbonate enclosure products, Fibox has...

SPM manufacturers a wide range of NEMA rated electronic enclosures. We are certified by UL to manufacture and sell various enclosure types such as 1, 3R, 4, 4X, 12K, and 13. Each type or rating is manufactured and tested to provide a degree of protection against certain environmental conditions per the standards of UL and NEMA.

More Aluminum Enclosure Manufacturers

Aluminum Enclosure Design

Aluminum enclosures can have a closed lid or a hinged door that can be secured, depending on the application. Corner screw covers and bezels conceal the mounting hardware, while continuous flanges or internal gaskets keep out dust and moisture. Labels, foil keyboards, and other alterations are all possible because of recessed areas in the enclosure's surface. Since aluminum is tough and has great structural strength, they frequently stand independently. Aluminum is forced through a die to form the correct cross-section used to make several enclosures.

Enclosures can also be cast or manufactured of rolled aluminum sheets and finished with a powdered coat or enamel. Depending on the purpose, these enclosures can be manufactured to specific requirements. Similar to the IP Code, NEMA offers safety ratings and certifications. They do not, however, map onto one another because they have various traits. Different NEMA types are used, such as 1, 3R, and 12. They cover everything from non-hazardous indoor use to outside protection from snow, rain, ice, and sleet.

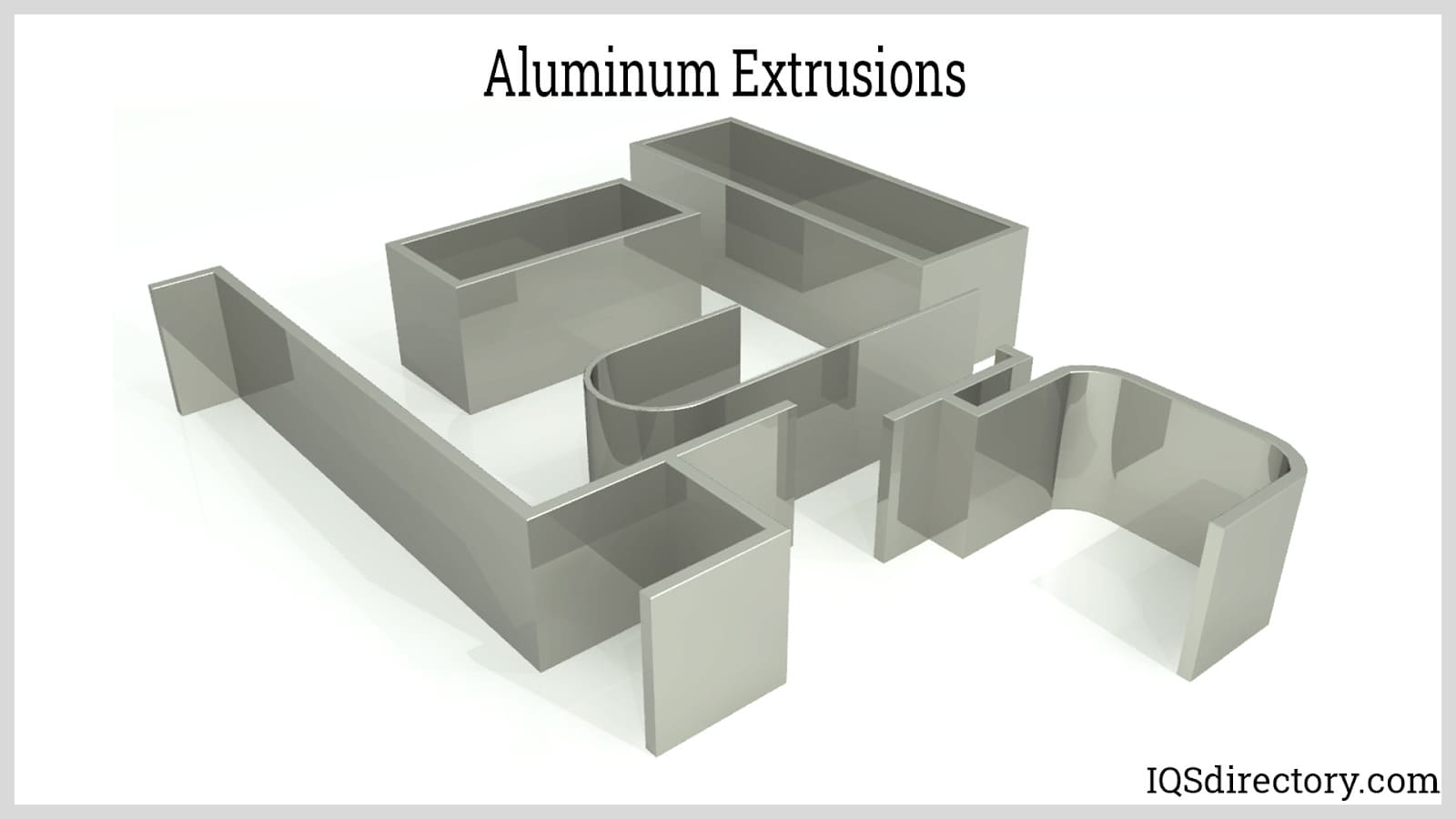

Types of Aluminum Enclosures

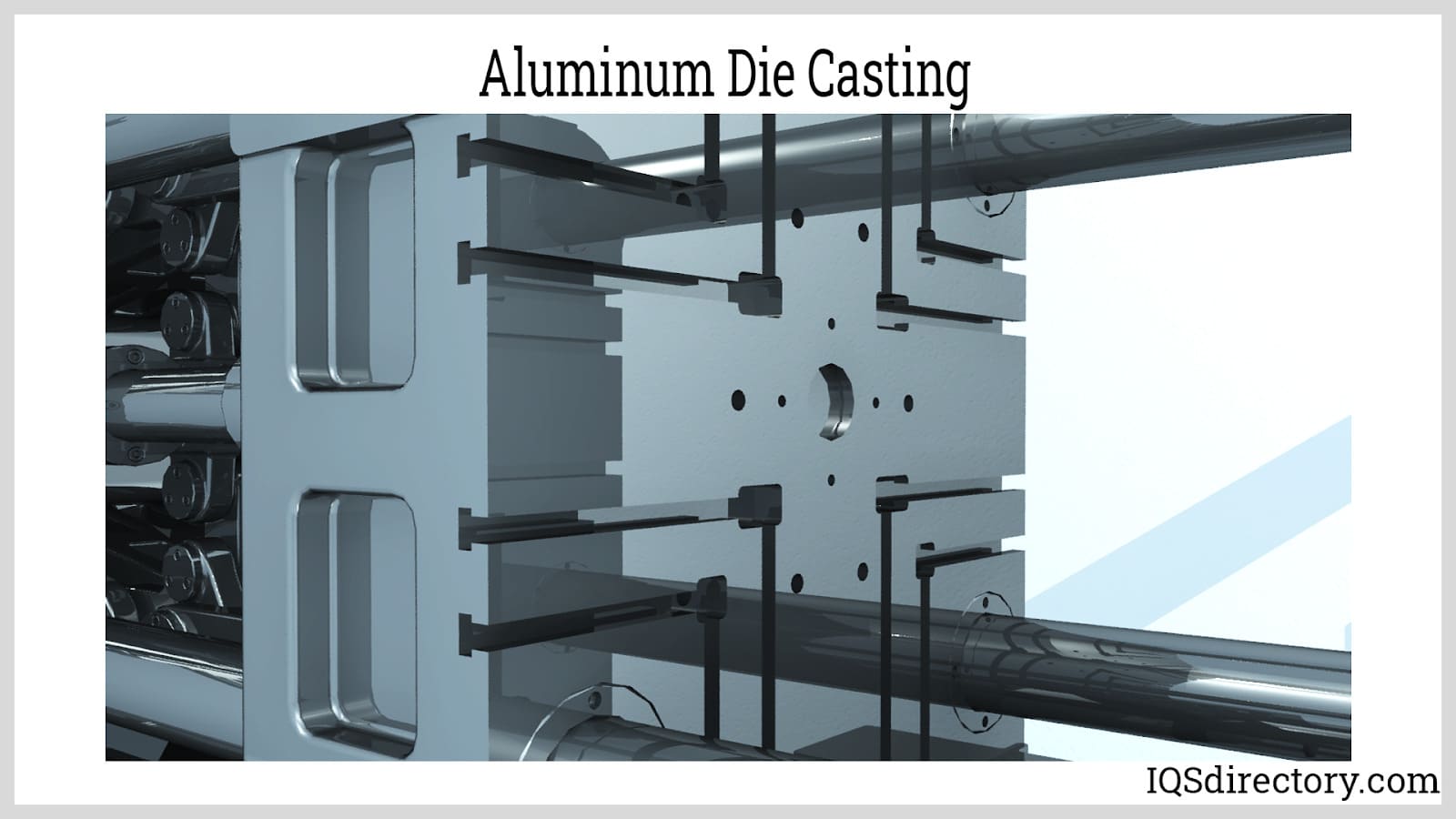

Die Cast Aluminum Enclosures

In the well-known metal production technique known as die casting, molten metal is forced into a closed mold, also known as a die, to generate the desired forms. Then, the mold is removed, and the cast is expelled once the material inside has cooled.

Applications

Aluminum is a popular option for elevated-pressure die casting due to its many advantageous properties. In addition, aluminum is useful for various indoor and outdoor uses due to its strength and elasticity, which can be improved by blending it with other metals. They can also be found in many medical devices where removing EMI/RFI interference is essential.

For instance, die cast aluminum casings frequently protect switchboards and meter boxes in various industrial situations. In addition, in many healthcare devices, where reducing EMI/RFI interference is crucial, die cast aluminum enclosures are used because of their inherent RFI/EMI shielding level.

Advantages

The die casting method is perfect for individuals who need intricate pieces since it uses molten metal to create the precise shape of the die. The fact that die casting produces lighter, thinner walls is another significant benefit. Die casting doesn't require a thick product, unlike the extrusion production process. The result is an aluminum enclosure that is thin, light, and has a lovely surface finish.

Disadvantages

Die cast aluminum enclosures are a preferred option for design engineers because of their resistance to corrosion and EMI shielding qualities. However, several things could be improved in this manufacturing process. Die casting is more suited for high-volume production because of its high upfront cost. Another typical issue with diecasting is porosity, which is brought on by trapped air in the steel die.

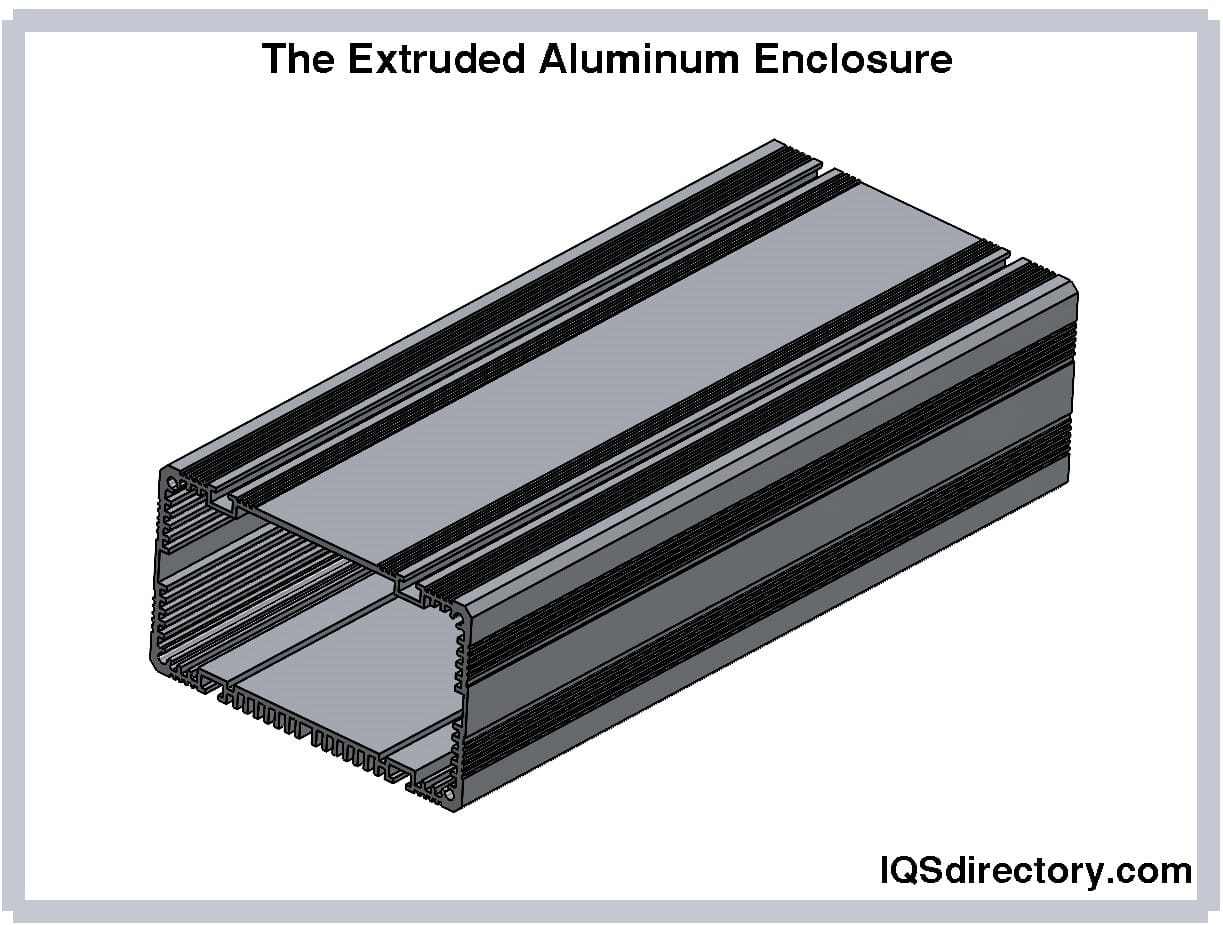

Extruded Aluminum Enclosures

Aluminum is inserted in an extrusion press during the extrusion process, where it is then pushed through a die by a hydraulic ram. The outcome is a lengthy part that can be chopped or machined as required.

Applications

Aluminum extruded enclosures can be seen in outdoor and indoor settings because they are made to endure dust and water. They are most frequently used to safeguard PCBs (printed circuit boards) in information systems, monitors, the Web of Things, medical applications, and various information systems.

Advantages

Engineers can profit from a variety of advantages of extruded aluminum enclosures. Multiple extruded aluminum enclosures also come with features that offer protection from various environmental variables. For instance, the extruded aluminum enclosures provide EMI shielding and waterproof gaskets and are built to comply with international aluminum enclosure requirements such as NEMA.

Installation takes less time with extruded aluminum enclosures because the PCBs may slip in. In addition, extruded aluminum casings ensure that extreme temperatures won't harm the delicate PCB components by having exceptional heat dissipation capabilities.

Disadvantages

The extrusion method has some limitations on assembly techniques and can only produce a finite number of shapes. In addition, the end caps also need to be produced separately.

Industrial Applications

Aluminum enclosures are employed in practically every industry that needs electrical equipment because of the variety of sizes available. Computers can be installed inside an enclosure for protection or purchased with aluminum unibody enclosures. Aluminum is widely used to enclose handheld gadgets. Examples of small remotes include garage door openers and car starters. Aluminum enclosures shield electrical conduits, power switches, and other crucial controls to avoid accidental contact between the box's contents and people or objects.

Selecting the Correct Aluminum Enclosure Supplier

For the most beneficial outcome when purchasing an aluminum enclosure from an aluminum enclosure supplier, it is important to compare several companies using our directory of aluminum enclosure suppliers. Each aluminum enclosure supplier has a business profile page illustrating their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each aluminum enclosure business website using our proprietary website previewer to get a better idea of what each company specializes in. Then, use our simple RFQ form to contact multiple aluminum enclosure businesses with the same form.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

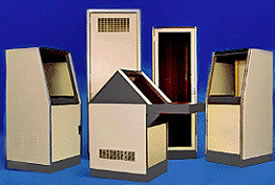

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services