Plastic enclosures serve as protective housings designed specifically for electronic applications. These enclosures are widely used across various industries due to their versatility and effectiveness in safeguarding electronic components. Whether it’s a consumer electronic device or an industrial control panel, plastic enclosures offer a reliable solution for enclosing and protecting sensitive electronics from environmental factors, physical damage, and electrical hazards. Read More…

Maysteel provides complex sheet metal fabrication with a focus on design for manufacturing. Founded in 1936, we combine our extensive engineering experience and market knowledge with an expanding supply chain footprint, allowing us to fabricate products that others can’t. We design, engineer and manufacture custom OEM sheet metal enclosures, kiosks, cabinets and racks. We have locations in the...

ROLEC Enclosures Inc. is a leading manufacturer of electronic enclosures. We work without clients’ needs and requirements to find the best solution for them. We also make fully customized enclosures to be ready for use immediately. Give us a call today learn how ROLEC Enclosures can help you will all your enclosure needs.

AutomationDirect.com takes pride in being a trusted partner for businesses seeking reliable electronic enclosure solutions. Our team is dedicated to providing exceptional customer service and technical support to ensure that our customers find the perfect products to meet their needs.

With over 80 years of collective expertise, AMCO Enclosures stands as a pioneer in crafting and delivering top-notch electronic enclosures. Our forte lies in electronic packaging, server rack, network rack, and containment manufacturing, making us the go-to choice for diverse industries.

At Accurate Metal Fabricating, we specialize in crafting precision-engineered electronic enclosures that meet the unique demands of modern industries. With a relentless commitment to quality, we pride ourselves on providing cutting-edge enclosures that safeguard electronic components with unparalleled accuracy. At the heart of our success is a passion for innovation, driving us to create...

Fibox Enclosure Systems is one of the largest enclosure manufacturers in the world and is the market leader in thermoplastic enclosures used for protecting electrical and electronic components in hostile and hazardous environments. Fibox recently celebrated over 40 years as a designer and manufacturer of thermoplastic enclosures. Besides pioneering polycarbonate enclosure products, Fibox has...

SPM manufacturers a wide range of NEMA rated electronic enclosures. We are certified by UL to manufacture and sell various enclosure types such as 1, 3R, 4, 4X, 12K, and 13. Each type or rating is manufactured and tested to provide a degree of protection against certain environmental conditions per the standards of UL and NEMA.

More Plastic Enclosure Manufacturers

Components of Plastic Enclosures and Their Functionality

Plastic enclosures consist of several components that work together to provide optimal functionality. The housing forms the main structure, providing a secure enclosure for the electronic components. Mounting options such as internal PCB (printed circuit board) standoffs and external brackets facilitate the installation and assembly of electronic boards. Additionally, cable management features allow organized routing and protection of cables, reducing clutter and improving overall system integrity. Sealing and protection features, meanwhile, including gaskets and O-rings, ensure the enclosure is resistant to water, dust, and other contaminants. Furthermore, accessory integration options enable the addition of switches, connectors, display windows, and other components. Finally, ventilation and cooling mechanisms, such as vents and heat sinks, help dissipate heat generated by the enclosed electronics, preventing overheating and ensuring optimal performance.

Variations of Plastic Enclosures

Plastic enclosures come in various forms to cater to specific application requirements. Desktop plastic enclosures are commonly used for home automation control panels, providing an elegant and functional interface for users. Handheld plastic enclosures, meanwhile, offer portability for devices like handheld meters, remote controls, and medical instruments. Rack-mount plastic enclosures, on the other hand, are designed to fit standard server racks and are used for housing networking equipment and servers. Additionally, wall-mount plastic enclosures are popular for security systems and home automation hubs, providing convenient and secure installation options.

Types of Plastic Used for Plastic Enclosures

Different types of plastic are utilized in the manufacturing of plastic enclosures, each offering unique characteristics suitable for specific applications. ABS (Acrylonitrile Butadiene Styrene), for example, is commonly used for its durability, impact resistance, and versatility, making it suitable for consumer electronics and industrial control panels. Polycarbonate, meanwhile, is known for its high impact resistance and transparency, making it ideal for outdoor electronics and automotive applications. Nylon is a robust choice for harsh environments and heavy-duty equipment due to its strength and resistance to chemicals. Furthermore, PVC (polyvinyl chloride) is preferred for electrical and electronic enclosures requiring insulation properties.

Considerations Regarding Plastic Enclosures

While plastic enclosures offer numerous benefits, some considerations need to be addressed. One concern is the environmental impact associated with plastic production and disposal. Additionally, plastic enclosures may not possess the same level of durability and mechanical strength as metal enclosures, which can impact their longevity in certain demanding environments. Moreover, plastic enclosures may face challenges related to heat dissipation and temperature resistance, requiring careful design considerations to mitigate these issues.

Manufacturers Address These Considerations

Manufacturers of plastic enclosures have been taking proactive steps to address these considerations. For example, they have introduced sustainable material sourcing initiatives focused on utilizing recycled or environmentally friendly materials, reducing their ecological footprint. Design optimization techniques have also been employed to enhance the durability of their plastic enclosures, making them more resistant to impact and wear. Furthermore, improved thermal management solutions, such as integrated heat sinks and ventilation designs to help dissipate heat effectively and ensure proper temperature regulation, have also been introduced. Lastly, recycling and disposal initiatives, such as encouraging responsible disposal practices and promoting the recycling of plastic enclosures, have been promoted in an effort to minimize environmental impact.

Benefits of Plastic Enclosures

Despite these considerations, plastic enclosures offer several advantages. They are cost-effective compared to metal enclosures, making them an attractive choice for budget-conscious projects. Plastic enclosures are also lightweight, enabling ease of transportation and installation. Moreover, they offer excellent customization options, allowing for easy modifications and adaptations to accommodate specific electronic components and user requirements. Plastic enclosures additionally possess electrical insulation properties, reducing the risk of electrical hazards. Furthermore, they exhibit good corrosion resistance, making them suitable for outdoor and humid environments. The versatility in design and functionality of plastic enclosures enables manufacturers to create a wide range of shapes, sizes, and features, meeting the diverse needs of various electronic applications.

Applications of Plastic Enclosures

Plastic enclosures find applications in numerous industries and electronic devices. In home automation systems, for example, they serve as control panels, housing smart home devices and providing user interfaces for seamless automation. Medical and healthcare devices, such as patient monitoring systems and portable medical instruments, also rely on plastic enclosures for compactness, durability, and ease of use. Industrial control panels utilize plastic enclosures to house sensitive electronic components and ensure reliable operation in demanding industrial environments. Meanwhile, automotive electronics, including car infotainment systems and control modules, benefit from the impact resistance and customization options of plastic enclosures. Furthermore, consumer electronics like gaming consoles, routers, and smart devices employ plastic enclosures for their aesthetic appeal, lightweight design, and cost-effectiveness. Telecommunications equipment, such as network switches and routers, additionally, use plastic enclosures for their electrical insulation properties and versatile form factors.

Choosing the Correct Plastic Enclosure Manufacturer

To ensure you have the most positive outcome when purchasing plastic enclosures from a plastic enclosure manufacturer, it is important to compare several companies using our directory of plastic enclosure manufacturers. Each plastic enclosure manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each plastic enclosure business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple plastic enclosure companies with the same form.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

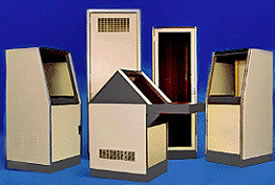

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services