Instrument enclosures protect electronic devices inside metal or plastic housing. Because of their sensitive circuitry, the components must be protected from dirt, water and accidental contact. Being kept in an enclosure prevents the intrusion of solid foreign objects as well as liquids to a certain extent. Instrument enclosures are made from aluminum, acrylonitrile butadiene styrene (ABS) plastic, stainless steel and, for certain models, polyester with fiberglass reinforcing. Read More…

Maysteel provides complex sheet metal fabrication with a focus on design for manufacturing. Founded in 1936, we combine our extensive engineering experience and market knowledge with an expanding supply chain footprint, allowing us to fabricate products that others can’t. We design, engineer and manufacture custom OEM sheet metal enclosures, kiosks, cabinets and racks. We have locations in the...

ROLEC Enclosures Inc. is a leading manufacturer of electronic enclosures. We work without clients’ needs and requirements to find the best solution for them. We also make fully customized enclosures to be ready for use immediately. Give us a call today learn how ROLEC Enclosures can help you will all your enclosure needs.

AutomationDirect.com takes pride in being a trusted partner for businesses seeking reliable electronic enclosure solutions. Our team is dedicated to providing exceptional customer service and technical support to ensure that our customers find the perfect products to meet their needs.

With over 80 years of collective expertise, AMCO Enclosures stands as a pioneer in crafting and delivering top-notch electronic enclosures. Our forte lies in electronic packaging, server rack, network rack, and containment manufacturing, making us the go-to choice for diverse industries.

At Accurate Metal Fabricating, we specialize in crafting precision-engineered electronic enclosures that meet the unique demands of modern industries. With a relentless commitment to quality, we pride ourselves on providing cutting-edge enclosures that safeguard electronic components with unparalleled accuracy. At the heart of our success is a passion for innovation, driving us to create...

Fibox Enclosure Systems is one of the largest enclosure manufacturers in the world and is the market leader in thermoplastic enclosures used for protecting electrical and electronic components in hostile and hazardous environments. Fibox recently celebrated over 40 years as a designer and manufacturer of thermoplastic enclosures. Besides pioneering polycarbonate enclosure products, Fibox has...

SPM manufacturers a wide range of NEMA rated electronic enclosures. We are certified by UL to manufacture and sell various enclosure types such as 1, 3R, 4, 4X, 12K, and 13. Each type or rating is manufactured and tested to provide a degree of protection against certain environmental conditions per the standards of UL and NEMA.

More Instrument Enclosure Manufacturers

Instrument enclosures come in many varieties to accommodate the wide array of electronic instruments. For small handheld instruments, enclosures may be custom-contoured to the shape of the device and designed to provide long-lasting protection and shock absorption. Desktop instruments can generally be housed in a box-like enclosure that is manageable in size and durability, protecting against spills and accidental contact.

Wall mounted enclosures keep their contents close to the electronic equipment the instruments control while shielding them from dust, dirt, splashing water and other undesirable contact. Electronic instruments are used in many applications, especially for precision work in scientific, engineering, medical and technological fields. Possible instrument uses include control panels, operation switches, measuring devices and more. New ways of making enclosures safe and effective are constantly being researched due to the demand for and critical nature of electronic instruments.

The parts of an instrument enclosure vary depending on the application. Hand held enclosures may have slide-on covers or a knockout for a LCD screen. Desktop enclosures may have vents, handles, locking mechanisms and membrane keyboards while wall mounted enclosures are frequently hung on DIN rail with the ability to slide into position.

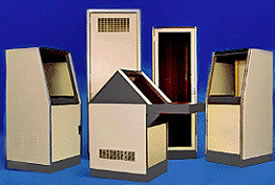

Other options incorporate neoprene seals or watertight gaskets, transparent lids or covers, recessed areas for labels or keypads, cylinder catches, lock covers, thermometers, drains, air dyers and special coatings to shield the contents from static electricity or EMI/RFI (electromagnetic and radio frequency interference). Metal enclosures can be constructed of cold rolled sheet metal that is welded for a smooth seam; aluminum is usually extruded.

Plastics, fiberglass and composite materials are gaining favor in certain situations because of their corrosion resistance, durability and weight. No matter what the material is, however, there are certain standards to which all enclosures must adhere. NEMA, the National Electrical Manufacturers Association, UL, the Underwriters Laboratories and the IP Code, or the International Protection Rating are all used to identify the enclosure's strengths and applicable functions as determined by the conditions they can withstand. For example, the common NEMA Type 4X enclosure can be used indoors or outdoors to protect its contents against corrosion, windblown dust, rain, sleet, snow, splashing or hose-directed water and the external formation of ice.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

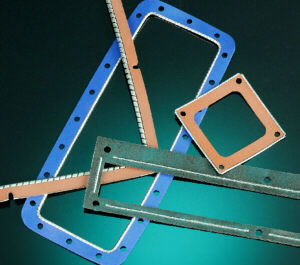

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services